Overhauling the Huosai HS-6 engine with Aerometal, our partner in Hungary – twelve engines now shipped; a further nine on order!

History and background

A G Ivchenko developed the AI 14 engine in 1948 as a standard engine for all Russian light aircraft, producing 260 hp. In the early 1950s, Ivchenko began work on turbo-prop engines, and in their wisdom the Russian authorities decided to allow him to concentrate on turbine engines and then gave the basic AI 14 design to four different engine manufacturers. From the early 1960s, part of the original design bureau, based in Voronezh, Russia, came under the control of I M Vedeneev, and he undertook a significant redesign of the AI 14 in order to produce more power and developed the M 14 P engine of 360 hp. Although the basic engine was very similar, it was significantly strengthened to develop more power – for example the M 14 has six satellite gears in the gearbox, whereas the AI 14 has only three.

The basic AI 14 design was given to PZL in Poland, who made no significant changes and continued to produce the engine for many years, and of course it was the standard engine in the Wilga. The AI 14 design was also given to LOM in Czechoslovakia who again made various modifications to produce the M462 engine of 305 hp and used in the Zlin crop-spraying aircraft. Finally, the design was also given to the Chinese, together with the design of the Yak 18 A military training aircraft – of course the predecessor to the Yak 52. The Chinese decided to completely redesign the aircraft to produce the Nanchang CJ-6, but did very little to change the engine for their use. Several thousand Nanchang CJ-6 were manufactured, of course for the Chinese air force but also for the air forces of friendly countries.

Chinese overhauls of these engines

The Chinese government decided to sell large numbers of surplus used Nanchang aircraft into Western civilian markets where they have been a great success, and indeed are an excellent aircraft, and better in many respects than the Yak 52. At the same time, the Chinese offered overhauled engines to Western owners operating Nanchang aircraft. From what we have seen, these overhauls were not particularly high quality – seemingly disassembly; a good clean; new piston rings; grinding valves; possibly changing crankshaft bushings; painting and some test running. But certainly good enough for a good period of further use.

However, approximately four years ago, for reasons that are somewhat inexplicable, the Chinese government decided that they would not overhaul any engines unless for their own air force. We have not seen any explanation for this decision, and it does seem surprising that they would not even overhaul engines for friendly air forces using Nanchang aircraft – and indeed we have been approached by the air forces in both Sri Lanka and Bangladesh to see if we could overhaul their HS-6 engines.

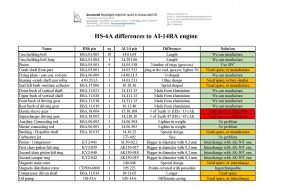

Technical differences between AI-14 and HS-6 engines

Three years ago, we obtained two HS-6 engines and carefully dismantled them, comparing every component both in terms of material used; dimensions and so forth with the AI 14 engine with which we are very familiar. As we expected, the differences were relatively small, and all the differences are given in the table below. As can be seen, the differences are typically not significant, and probably the only one of significance is the change in the supercharger drive ratio – and clearly this is where the additional 25 hp increase was obtained with the Chinese engine. However, again as can be seen from the table, we have worked out the solution to all these small differences in terms of overhauling the Chinese engine.

Our program to overhaul the Huosai engine

We see there being two somewhat different markets for these overhauls. Firstly, for the military market, and indeed we are in discussions with the air forces in both Bangladesh and Sri Lanka; we can see that their requirement is for an engine that is absolutely standard, so our proposals have been to keep the engine as original as possible, but to use the significantly superior Carrillo pistons, which are made of a far better aluminium which expands at almost the same rate as the steel cylinder so the clearance when cold can be considerably reduced, thus minimising oil consumption; preventing fouled sparking plugs and also giving additional power. And also the technical specialists in these air forces seem to accept the idea of our excellent automotive plug conversion. But otherwise the engines would remain as standard.

We see there being two somewhat different markets for these overhauls. Firstly, for the military market, and indeed we are in discussions with the air forces in both Bangladesh and Sri Lanka; we can see that their requirement is for an engine that is absolutely standard, so our proposals have been to keep the engine as original as possible, but to use the significantly superior Carrillo pistons, which are made of a far better aluminium which expands at almost the same rate as the steel cylinder so the clearance when cold can be considerably reduced, thus minimising oil consumption; preventing fouled sparking plugs and also giving additional power. And also the technical specialists in these air forces seem to accept the idea of our excellent automotive plug conversion. But otherwise the engines would remain as standard.

However, for the civilian market, we believe an important issue is the need to produce an engine of significantly more power than standard, which would hopefully overcome the natural tendency of some owners to go to the considerable extra expense of converting their aircraft to the M 14 engine, which involves important airframe modifications and of course the requirement for a new propeller. So we set ourselves the target of developing an engine which, at increased rpm, would be capable of delivering 370 hp, on the calibrated dynamometer at Aerometal.

The modifications required for increased power

Our program includes:

- Using higher compression pistons. The standard compression ratio of both HS-6 and M 14 P is 6.2:1. With our most powerful M 14 PF engines we use pistons giving a compression ratio of 8.2:1, but for the Huosai, we are having pistons manufactured by Carrillo in the USA with a compression ratio of 7.4:1 which we feel is an appropriate compromise between power and long life.

- An important part of our development of the M 14 family of engines is to have recognised that they were originally manufactured on a production-line basis with semi-skilled workforce and so they were allowed quite significant tolerances in dimensions. In particular within the supercharger, the closer the rotating impeller can be placed to the fixed diffuser, the greater the boost pressure will be and so the greater the power. So with very careful assembly, we have demonstrated that our supercharger assembly will give an additional 25 hp with the M 14 engine.

- The use of our latest automotive plug conversion kit, as standard, together with our new AYC magneto coils, both of which have been extremely successful and have been fully authorised by EASA.

- Using standard engine tuning technology, we have made sure that all induction passages are smooth with minimum resistance to airflow.

- We have increased maximum rpm.

Changing the QHQ-14A carburettor for the Russian M 14 V carburettor during overhaul

The Chinese carburettor is a direct copy of the original Russian AI14 carburettor and a somewhat simple device. The M 14 V carburettor is designed for the M 14 V helicopter engine, a much later engine and more sophisticated. In particular, we have a range of up to 10 different suction jets (in fairness we seldom need them at either end of the scale) for the M 14 V carburettor, whereas the Chinese carburettor only has three different suction jets, so the M 14 V is much more “tunable”. And in consequence will deliver a little more power at high RPM. It also has a simple but very effective automatic altitude compensation system, exactly the same as in the M 14 P carburettor, which works very well. There is an additional cost to fit the M 14 V carburettor, please contact us for further information.

Micro-polishing of gears

Micro-polishing is a specialised treatment of gears in which the surface of the gear is very carefully polished in the areas that it is meshing with another gear which can significantly reduce friction, and therefore release more power and reduce oil temperatures. We did extensive research on this, working with the well-known UK producer of automotive competition gearboxes, Hewland, and decided that there were 10 specific gears in the HS-6 engine which would benefit from this treatment. The most important are the three satellite gears in the drive gearbox and the associated ring gear. In addition, we also micropolish the six gears in the accessory and supercharger drives. We estimate that micro-polishing will produce an additional 4/5 hp, and reduce oil temperature by 7/10°C. There is an additional cost for micro-polishing, please contact us for more details.

Our overhauls of HS-6 engines

These include painting the engine in the colour of the customer’s choice, and of course we can use different colours for separate parts like magnetos; valve covers et cetera; nickel plating of all exposed metal parts; incorporating our new automotive plug conversion kit and our AYC coils; the high-compression Carillo pistons with modern piston rings; assembly to much tighter tolerances; balancing to a factor that is three times as good as originally allowed; every part of the engine totally overhauled to a condition that we believe is better than factory new since we are using skilled specialists rather than production-line workers; testing the engine for a minimum of three hours on a proper dynamometer and all results given to the customer. For overhaul costs, please see our Engines for Sale page.

The current position

Our first HS-6 engine produced 354 hp at 2500 rpm. We decided to increase this test rpm for the second engine, and at 2350 rpm it produced 308 h p; at 2500 rpm, 355 hp and a very impressive 378hp at 2600 rpm. We would only recommend that owners would use 2600 rpm for short periods, although it should be noted that our higher powered versions of the M 14 PF operate at 3100 rpm, but of course it is a stronger engine with stronger connecting rod; bigger piston pins and so forth.

p; at 2500 rpm, 355 hp and a very impressive 378hp at 2600 rpm. We would only recommend that owners would use 2600 rpm for short periods, although it should be noted that our higher powered versions of the M 14 PF operate at 3100 rpm, but of course it is a stronger engine with stronger connecting rod; bigger piston pins and so forth.

This issue of engine rpm is interesting. The AI 14, on which the HS-6 is based, and indeed both engines are almost identical, apart from the increased supercharger gearing of the Huosai, developed 260 hp at 2250 rpm, and the increase in supercharger speed is the reason for the additional 25 horsepower with the Huosai. But the Russians developed the AI 14 RF version which was absolutely unchanged, but developed 300 hp at higher rpm. Our understanding that this was at 2450rpm, but it is clear that increasing rpm makes a significant contribution to power on these engines.

As part of this process we have prepared a detailed overhaul manual complete with all the Chinese part numbers as well as making a new and perfect data plate for all new engines.

In order to take advantage of this enhanced power, it’s clear that the engine will require a much more efficient propeller. So we have been discussing the issue with GT propellers in Italy, and who have designed a new propeller, based on the existing Huosai propeller hub but with modern blades, and this has proved very successful in testing and is in current production. In addition, Hercules Propeller in the UK are also designing a new propeller.

Having now delivered twelve perfect Huosai engines, we are currently working on orders for a further nine Huosai overhauls, all to the same specification, but in various paint colours. While we cannot begin working on any other engine for at least three months, as per our normal practice we will place new orders in the order that they are given to us; we make no up-front charge; we only charge a 15% deposit when we actually start working on the engine – whether the customer’s own engine or one from our stocks – and then a final 85% only when the engine has been successfully tested and the results given to our customer.

Reviews from some very satisfied Huosai customers:

- “Quick acceleration and raw power…blown away by the performance.” “ All I can say is WOW! This engine is smooth and super responsive.” “Just completed my first annual since overhaul. All cylinders 78+/80. Burning only 1 quart every 8+ hours. Super dry. Engine is smooth topping out at 2575RPM, closer to 390 on HP.” Bill Mills

- “The engine started effortlessly and ran extremely smooth. No vibration whatsoever.” Greg Wrobel

- “A beautiful Aerometal Housai… I’m so impressed with the quality of their work. Engine started right up and performed flawlessly on the ground. The first flight came back with zero engine discrepancies” Jason Berman

- “Very pleased with the power and performance” Brian Youmans

- “Runs great, nice and dry, climbs like crazy. 500 FPM more initial climb rate, 10 more Kts cruise at same fuel burn, 7 hours so far and no perceptible oil consumption. All at stock RPM.” Andrew Wait

- “Your engine is a piece of art and is what swayed me to purchase this CJ over others.” Jeff Greenwood, HS-6